Our Plant & Project Profile

OBJECTIVE

To develop and implement a sustainable manufacturing process for corrugated boxes that reduces environmental impact while maintaining high-quality standards.

PROJECT DESCRIPTION

Corrugated boxes are essential for packaging and shipping across various industries due to their durability, lightweight nature, and cost-effectiveness. This project aims to enhance the sustainability of corrugated box production by integrating eco-friendly materials and innovative manufacturing techniques.

Material Selection

- Use of recycled paper and sustainable raw materials

- Sourcing from certified suppliers to ensure responsible forestry practices

- Multiple paper grades available for different strength requirements

Quality Assurance

- Rigorous testing for strength, durability, and performance

- Compliance with industry standards and regulations

- Regular quality audits throughout the production process

- Advanced testing equipment for precise measurements

Design Innovations

- Development of modular and reusable box designs

- Incorporation of biodegradable adhesives and inks

- Customization options to meet specific client needs while reducing material usage

Manufacturing Process

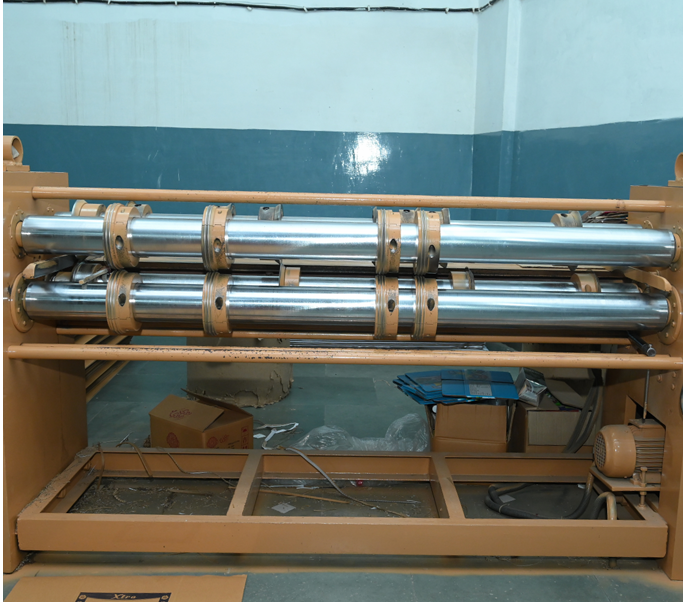

- Implementation of energy-efficient machinery

- Reduction of water usage through closed-loop systems

- Minimization of waste by optimizing cutting and assembly processes

- Continuous monitoring and process improvement

Environmental Impact

- Regular audits to monitor carbon footprint

- Initiatives to offset emissions through tree planting and other green projects

- Education and training programs for employees on sustainable practices

- Waste reduction and recycling programs

CORRUGATION E-FLUTE MACHINE

DIE MACHINE SMALL

ROTARY MACHINE

PASTING MACHINE

DIE MACHINE BIG

ROTARY SLOTTING

GLUEING MACHINE

CORRUGATION A- FLUTE MACHINE

ROTARY SLOTTING (4) 2 COLOUR PRINTING

FLEXO PRINTING

CORRUGATION B- FLUTE MACHINE